Future-proof mixing technology for battery production

Eirich presents pioneering innovations at Battery Show Europe

The rapid development of new cell chemistry and electrode strategies in battery production is demanding flexible, future-proof mixing systems. Eirich is responding to this with innovative technology that combines flexibility with investment security to meet the technological requirements of the industry.

Hardheim, May 2025: At Battery Show Europe, Eirich will be presenting its advanced mixing systems under the motto “One system for everything.” The company offers solutions for lithium-ion, sodium-ion, and all-solid-state batteries, and at the trade fair the spotlight will particularly be on the 500-liter mixer RLV12W Vac, as well as on the laboratory mixers C5 and the new El1nano as the highlight for the development of new solid-state batteries with its capacity of up to 100 ml.

Future-proof mixing technology for every electrode strategy

“These mixing systems are able to support wet, semi-dry, and dry electrode processes and are the perfect response to the key issue in the industry: ‘How can I ensure that my investment is future-proof – regardless of the specific direction taken by cell technology developments in the future?‘ Universal applicability is particularly important, as battery researchers are still working hard to optimize the performance and sustainability of the cells,” says CEO Stephan Eirich. In the process, the main thing that sets Eirich apart from its competitors is the very fundamental way in which the Eirich mixing principle differs from the method of operation of planetary mixers and extruders, offering uniquely low energy consumtion, improved homogenization, and unrivaled flexibility.

Comprehensive battery electrode production lines – from raw materials to coating machines

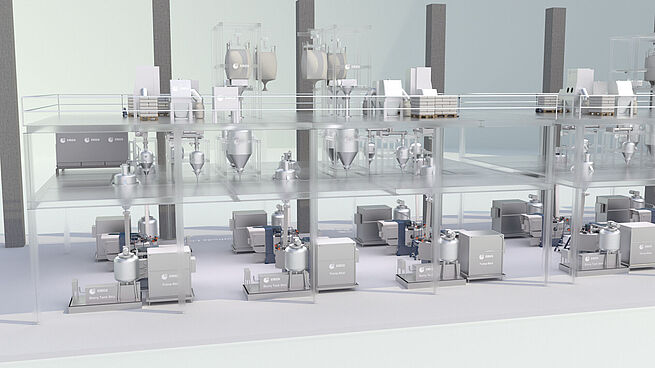

Eirich will also be presenting a comprehensive concept for electrode manufacturing, covering the entire production process from raw materials input and dosing to the transfer of the prepared electrode compound to the coating machine or calender. In terms of dry electrode production, this also includes the material transfer downstream of the mixer and the return/recycling of production waste. This means that Eirich covers all aspects from a single source – offering unrivaled process reliability, minimized interface risks, and faster time-to-market. On top of this, Eirich batch processes require significantly shorter mixing times – enabling companies to achieve the same or greater output with smaller machines, which directly benefits their CO2 footprint and reduces overall investment costs.

The digital 3D model at the company’s booth will provide trade fair visitors with an expandable visualization of the processing line.

Efficiency and quality as important success factors

As well as offering insight into the technology behind its mixing principle, Eirich will also be highlighting how line costs and operating costs can be reduced through more compact and modularized system design. This is in keeping with industry trends to optimize production layouts in order to save space and reduce costs, which plays an ever more important role in large-scale manufacturing projects.

The quality assurance systems, including inline monitoring and rheological measurement methods, ensure efficiency and consistency. Eirich employs modular and standardized machine concepts to shorten commissioning times and enable fast ramping-up of production – which is pivotal for projects in gigafactories all around the world.

Global references at gigawatt scale

“Our international reference projects in the gigafactory segment demonstrate our versatility and depth of experience in the field of battery technology. Our customers put their trust not only in our know-how and expertise, but also in our understanding of industry-specific production processes. Eirich is a dependable partner who stands for investment reliability and technological progress – far beyond that of conventional PD mixers,” adds Dr. Stefan Gerl, Head of Process Engineering at Eirich.

The trade fair will be a great opportunity for visitors to gain insight into the latest developments that are taking place at Eirich and to find out all about state-of-the-art mixing technologies at industrial scale that are superior to conventional mixers in all areas.

Battery Show Europe will take place from June 3-20 at the exhibition center in Stuttgart/Germany. The stand of mixing specialist Eirich can be found in hall 10 at booth H50. Eirich is also part of the VDMA Guided Tour, which will take place under the motto “Meet the European Battery Innovators.”